More news

- Focus on industrial: Powering the energy industry during extreme heat

- Focus on powder coatings: The coatings industry’s transition to PFAS/PTFE-free solut...

- “We see sustainability as a purpose, as a reason for doing business” – P...

- Focus on industrial: High-performance coating protects tanks at biopolymer production plan...

- Focus on powder coatings: Novel high-speed crosslinking technology

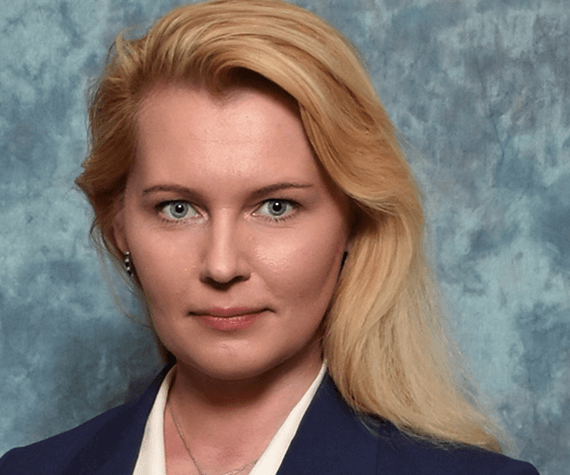

Ahead of the upcoming Middle East Coatings Show, PPCJ spoke to Olga Kolevatova, PPG General Manager of the Middle East, Egypt, Turkey & Caspian Region, to discuss the latest trends, opportunities and advancements in the Middle East’s coatings industry

Q. What manufacturing plants and capabilities does PPG have in the Middle East and what sectors does PPG cater to in this region?

A. PPG has been active in the Middle East paints and coatings market since 1999. With the acquisition of Sigma Coatings in early 2000, PPG gained a larger share of the local market. The company serves customers in the protective, marine, industrial, refinish and aerospace markets from four manufacturing facilities in the region.

Q. The Middle East is an increasingly prominent region for the coatings industry. What are the main opportunities for coatings manufacturers, in terms of being based in this region?

A. The Middle East presents significant opportunities for coatings manufacturers, primarily due to its growing construction and industrial sectors. The region’s harsh climate conditions drive demand for durable and high-quality coatings. Moreover, the increasing focus on sustainably advantaged products offers potential for innovation. The presence of large-scale infrastructure projects and the growing automotive industry also provide substantial market opportunities.

Q. What are the main challenges that the Middle East region presents for paint manufacturers?

A. One of the main challenges in the region is the harsh environmental conditions that require high resistance to heat, UV rays, dust and humidity. Coatings standards and regulations vary across different countries; and overcoming tariff and non-tariff barriers and customs procedures can also be a challenge.

Q. What are the main concerns/trends that your customers focus on when it comes to coatings?

A. The main concerns and trends that Middle East customers focus on are similar to those in other regions, namely sustainability, innovation, and quality of performance:

- Sustainability: Customers are increasingly focused on more sustainably advantaged solutions, including the development of coatings that minimise waste, use renewable or recycled materials and reduce their carbon footprint.

- Innovation: There is a strong trend towards the use of advanced technologies like artificial intelligence (AI) and machine learning to improve product development and quality control. These technologies enable rapid analysis, optimise manufacturing processes and ensure high-quality materials for our customers.

- Quality of performance: Next-generation coatings are being developed to meet customers’ requirements with enhanced features like heat-, UV- and corrosion-resistance, reduced carbon footprint and increased lifespan. Self-cleaning and antimicrobial coatings are also gaining popularity for their convenience and health benefits.

- Customers are also increasingly valuing comprehensive technical support throughout the lifecycle of a coating project. This includes expert advice and assistance before application (like surface preparation, for example), during application (such as proper technique and environmental considerations), and post-application (including maintenance and performance evaluation).

READ MORE:

It’s a wrap! Middle East Coatings Show welcomes record number of visitors to Cairo

Q. How important is sustainability in this region and what are the main challenges that PPG has already addressed?

A, The GCC countries have incorporated sustainability in their strategic vision and plans. The UAE leads the region, with actions including a target to reduce emissions by 40% by 2030 and sustainability requirements for publicly traded companies. It is also the first country in the region to announce a net zero target by 2050.

Saudi Arabia launched the Saudi Green Initiative as part of Vision 2030, aimed at increasing its reliance on clean energy and reducing carbon emissions. Qatar launched the National Climate Change Action Plan 2030 to enhance sustainability efforts and reduce its greenhouse gas emissions.

Our initiatives in sustainability are very much aligned with the region’s commitment. Notably, PPG is the first US-based company in the industry that has received validation from the Science Based Targets Initiative (SBTi) for its 2030 greenhouse gas (GHG) emissions targets.

Locally, we are among the first companies to receive approval under the UAE National In-Country Value (ICV) Program. It aligns with the broader goals of the UAE to promote economic diversification, grow local industries, and ensure sustainable and diversified growth.

In addition to emissions reduction targets, we take pride in developing sustainable solutions for our customers. We have developed an industry-leading methodology to classify which of our products are considered sustainably advantaged. For example, our sustainably advantaged products extend the useable lifespan of bridges and buildings, reduce energy use and GHG emissions by eliminating curing stages for our automotive coatings and sealant systems, make food and beverage containers safer and longer lasting, and even help improve the fuel efficiency of airplanes and cargo ships. In 2022, 39% of our total sales came from sustainably advantaged products.

To further strengthen our sustainability innovations, PPG has launched the PPG LINQ™ end-to-end digital ecosystem for the refinish market in Europe, the Middle East, and Africa in early 2023. Using a cloud-based platform, the PPG LINQ ecosystem allows body shops to become significantly more efficient. It embeds sustainability into day-to-day operations and minimizes environmental impact, with optimized product consumption and waste reduction.

Q. Does PPG have any more sustainability targets that it is still working towards?

A. PPG has committed to reduce absolute emissions from its own operations (scope 1 and 2) by 50% by 2030 from a 2019 base year. It has also committed to reducing absolute scope 3 GHG emissions from purchased goods and services, processing of sold products, and end-of-life treatment of sold products by 30% within the same timeframe. The company’s emissions reduction strategy for its operations includes energy efficiency projects and renewable energy sourcing. Within the value chain – or scope 3 – PPG is collaborating with suppliers to identify GHG emissions reduction opportunities and lower-carbon raw material sources.

In addition to the above targets which have been validated by SBTi, PPG’s other 2030 ESG targets against a 2019 baseline are:

- 50% of sales from sustainably advantaged products;

- 15% reduction in water intensity at priority sites;

- 25% reduction in waste intensity;

- Reuse, recycle or recover 100% of process waste;

- US$5M additional Colorful Communities® funding, with each project incorporating an element of sustainability, making the total investment US$15M since 2015;

- 100% of key suppliers assessed against sustainability and social responsibility criteria;

- 100% of employees go home safely each day;

- 5% annual reduction in spill and release rate.

READ MORE:

EU regulations round-up: September 2023 – Sustainability reporting standards loom

Q. Are there any other trends that are impacting coatings in the region?

A. A significant trend impacting this region is the strategic vision of regional governments, who are investing in world-class infrastructure and special economic zones. The purpose is to promote local value chains and develop new local industries and services. PPG is very appreciative and supportive of such programmes and as previously mentioned, is one of the first companies to receive approval under the UAE National In-Country Value (ICV) Program.

Another emerging trend in the construction and design industries is to take inspiration from the heritage, developing unique styles that capture the narrative and style synonymous with the rich heritage and history of the region and still meet the global sustainability agenda.

Q. Congratulations on being a Board Member of The Middle East Paints and Coatings Association (MEPCA). What does this entail and what does the association aim to achieve for coatings in the Middle East?

A. I am happy to have an opportunity to be a part of a supportive community that is invested in the potential of the industry and is leading meaningful conversations across the market.

We are still in a nascent stage, however, the need for and the importance of the association is clear from the fact that all our peers have readily agreed to come together as one to work for the long-term sustainable development of our industry and the region.

Q. You are also the only female board member. Do you think this gives you a different perspective? Do you have any issues that you personally want to focus MEPCA’s attention on?

A. A diverse workforce and inclusive culture promote employee well-being and are intrinsically linked to stronger company performance. PPG is consistently working to find new ways to amplify the voices of our underrepresented employees and help all of our employees bring their best selves to work.

We know that the power of seeing more women in the workplace and on public platforms encourages more women to strive for leadership roles and I am committed to see more women and diverse talent entering this industry.

The Middle East Paints and Coatings Association (MEPCA) is an association partner of the Middle East Coatings Show, which will take place in Dubai April 16-18, 2024.