More news

- View from the UK: Navigating chemical policy and sustainability

- Focus on adhesives: Unveiling unbreakable bonds – Testing redefines physical strengt...

- Focus on adhesives: Henkel and Covestro collaborate for sustainability of engineered wood ...

- Advances in construction chemical technology: What’s new in 2024?

- Focus on sustainability: PPCJ speaks to BASF Dispersions Asia Pacific about its holistic a...

Among non-metal substrate coatings, plastic substrates have certainly asserted themselves as a key market, especially in the automotive industry. The substrates within exterior automotive industries are being diversified and commercialised at a rapid pace. Mainly attributed to the emergence of electric vehicles, environmental regulations and functional requirements, there is huge scope and many opportunities for advancements and groundbreaking technologies.

The above factors have led to the dawn of new and improved coating materials within the revolutionising new substrate market. At the same time, new product innovations within ultraviolet (UV)-curable technologies, powder coating, nanotechnologies and several other platforms have brought the possibility of novel coating systems into the picture.

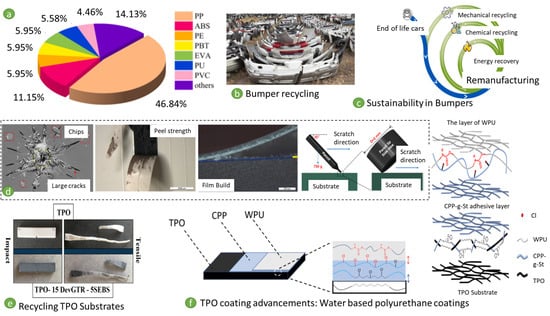

This review outlines the inherent challenges, the progress made thus far, and the future opportunities of two significant exterior plastic substrates: thermoplastic polyolefin (TPO) and polycarbonate (PC). While the former serves as the historical choice for plastic bumpers across the globe, the latter has captured the most research attention in recent times as a lightweight option against glass coatings.

A meticulous overview of the existing literature was conducted to summarise the recent approaches with a few critical analyses. To surpass the challenges to the equivalent performances, a few of the most promising research studies were also examined, including the sustainability aspect.

Introduction

Due to the widespread use of metallic substrates in numerous industries, the major share of coating research contributes to product coatings for metallic substrates [1]. However, product coatings for non-metallic substrates are also receiving a huge amount of attention currently [2]. This is particularly true for automotive exterior plastic substrates [3]. Having started off as an evolutionary change to better fit the exterior design, the automotive exterior plastic substrate market is undergoing a revolutionary change with the advent of electric vehicles (EVs). Most of these parts are coated either via an offline, online, or inline process. Among the three processes, a smaller number of substrate options are available for inline processing due to the high temperature curing of metal body coatings (160–180°C) [4]. Substrates like acrylonitrile butadiene styrene (ABS), polycarbonate (PC), polyamide (PA), thermoplastic polyolefin (TPO), polyurethane reinforced reaction in mould (PUR-RRIM), sheet moulding compound (SMC), polymethyl methacrylate (PMMA), and polybutylene terephthalate (PBT) are applied in mirror housings, coverings, grillers, bumpers, door handles, trims, spoilers, fenders, tail gates and lids, hoods, roofs, fascias, headlamp lenses, etc.

It is true that there are other non-metallic substrates like glass, paper, plastic films, interior automotive coatings and glass coatings, but herein, this review is confined to two of the most important exterior automotive plastic substrates: TPO and PC. The former is the foundational choice for bumpers across the globe, anticipating an imminent characteristic revolution, whereas the latter is gaining attention as a highly functional replacement for glass coatings [1]. ABS, another commonly used engineering plastic for automotive applications (more diverse interior automotive applications), is not included in this review.

The most challenging problem has been the coating adhesion of exterior plastic components like bumpers and fascias, which are inherently made from a polypropylene/ethylene/propylene/butadiene rubber blend [4]. This component is commonly referred to as “PP-EPDM” in Europe and Asia, and “TPO” in North America. Surely, several predetermined foundational coatings have become available for TPO since its inception in 1920 [5]. Environmental regulations on plastic waste, petroleum resources and the emergence of the lightweight electric vehicle market are a few factors influencing this very established TPO market [3]. Despite the long history of established TPO technologies, high-impact developments have been reported from a decade ago. As new modified substrates and other novel bio-based substrate markets are blooming [6,7], it is therefore critical that, as a scientific community, researchers across the globe are cognisant of the existing challenges relating to TPO and make progress to access the future opportunities of not just TPO, but also those of exterior plastic substrates as a whole. If TPO is a substrate that is undergoing rapid change and potentially will be replaced by other sustainable resources, PC, however, presents a whole new portfolio of opportunities within the automotive coating industry [8]. Being an interesting aspect of plastic substrates, these transparent coatings can be lightweight alternatives to glass coatings, though the former is a little more prone to scratch and wear [9]. To that extent, polycarbonate plastic has essentially gained attention due to its transparency, impact resistance and weatherability, especially in auto headlamp covers and signage [10]. It goes without saying that coatings on both substrates also need to pass the common property requirements of stiffness, tensile strength, flexibility, stone chip resistance, etc.

Therefore, looking at the evolving exterior automotive coating market, this concise review attempts to provide a new perspective on the possibilities and challenges of the current and future cure systems for plastic substrates themselves. The review tries to fill the knowledge gap that exists in the TPO market in terms of three aspects: what is being fundamentally used, the challenges and surge of new technological advancements and the substrate market, and a review on some of the recent innovations that would equip researchers to design products with advanced performance capabilities. However, in the case of the PC market, the knowledge gap is rather related to identifying the new chemistries and technologies that would provide a foundational horizon to design novel PC coatings, as they are on the verge of replacing glass coatings in several automotive parts. A simple yet effective scientific and technical perspective is presented here to provide an authoritative and up-to-date understanding and to assess its future opportunities.

READ MORE:

Overview of coatings for Tpo substrates

From the very beginning, the lower surface tension and mould release agents (silicone, fluorocarbon or wax mould) have been impeding TPO coating adhesion [5,11]. To that extent, water-soluble soap-based mould release agents have been reported as a better choice. Multiple sets of spray washing utilising detergent-based deionised water are employed. A surface treatment of a more established chlorinated polyolefin (CPO) solventborne or waterborne primer consisting of maleic anhydride-grafted chlorinated polypropylene has been used for promoting adhesion [12]. Through the support of fluorescence and Raman chemical imaging, the reported mechanism involves a chlorinated polymer diffusing into the surface layer of polyolefin and into the rubber phase.

Morris et al. established a way to envision the surface bulk distribution of CPO films over a TPO substrate using a tagged solvatochromic dye, Nile Red (NR) [12]. Moreover, confocal fluorescence chemical imaging conducted by the same research group exhibited a migration of a thin layer of elastomer (2–3 µm) onto the TPO surface [13]. CPO was localised near the TPO surface and PP at a microscopic range of 15µm below the surface, as per Raman point mapping and cosine correlation analysis. Several factors like the molecular weight, chlorination degree, maleic content, film thickness, CPO structure and moulding techniques were all considered as critical factors in the performance. Further, hydrocarbons and oven cure are reported to promote the penetration level of CPO into the TPO interface and the matrix [1]. However, polypropylene crystallinity reduction due to solvent swelling and cohesive failure due to thicker films and baking temperatures are two factors that need careful monitoring [4].

The presence of a solvent increases the surface penetration, but solvent crazing and solvent popping are common challenges. To tackle these challenges, scientists have reported a system with a lower solvent permeability, which would mean the utilisation of a higher cross-linked binder. With certain exceptions (TPO needing an adhesion promoter primer layer), the same base coats and topcoats designed for metal substrates can be used as plastic base coats and topcoats, respectively. Nunez et al., who studied the TPO adhesion promoter performance post UV exposure, reported an adhesion loss in as little as 100hr of UV exposure via an FTIR study [14]. Therefore, it is critical to have UV absorbers (UVAs) and hindered amine light stabilisers (HALSs) with hydroxyl functionality in the topcoat for plastics, since these OH groups can react with isocyanate groups in the clear coat and prevent its migration, binding the catalyzer onto the polymer chain [15].

Surely, there are options for the surface treatment of plastic substrates instead of a specialised CPO primer application. Some of the examples include using oxidised agents like chromic and sulphuric acid baths. Reactive gas processing using fluorine gas, oxidising flame using propane or butane, passing through corona or between dielectric barriers generating electrodes, atmospheric pressure plasma activation, plasma discharge and benzophenone spraying followed by UV irradiation are a couple of substrate treatment examples [1]. Even so, the numerous methods mentioned prior do not generally impart conductivity to the surface, which would enable electrostatic spraying and thus, conductive pigments filled with TPO primers are more preferred [16,17].

There has not been significant research very recently in the basic understanding of how coatings like CPO work on the TPO. Contrary to this general remark, however, Wang et al. [18] recently reported a water-based adhesive, which has polar recognition to both a TPO substrate and water-based polyurethane coating. Historically, the low-surface-energy hydrocarbon of polar water-based polyurethane (WBPU) did not impart good wet bonding on the TPO surface. However, Wang et al. [18] grafted styrene onto CPO using the phase inversion method as an emulsion adhesive. In the process of adhesion, the non-polar parts recognise and move towards the TPO side, while the polar parts recognise and move towards the WPU polar components, ultimately resulting in an enhanced bonding effect between the TPO and WBPU coatings. As evidence, they reported a reduction in the surface tension and an increase in the peel strength. It can certainly be an efficient solution for a coating or adhesive or coating between non-polar and polar substrates.

Performance testing advancements

Overall, the CPO coating has worked well over TPO for years, and the environmental factors and new evolutionary performance requirements are challenging its dominance, as opposed to a revolutionary change. Having looked at the fundamental research on TPO, it is critical that we review some of the testing requirements and recent years’ technical advancements before going to the next aspect. Among many necessary tests, stone-chip resistance (resistance of a coating layer against the impact of stones) is a key requirement, and Liu et al. [19] recently suggested that engineering stress–strain curves under dynamic tension load using the split Hopkinson tension bar (SHTB) demonstrated strong nonlinearity and strain rate correlation with brittle failure behaviour. The greater thickness of the paint films, the ellipsoid impact under high-impact speed, and cohesive failure under normal impact were factors that were unfavourable.

In earlier years, Buter et al. [20] utilised a controlled accelerated stone thrower (CAST) and discovered that contact type under impact had the most influence in regard to the coating failure mode. Ramamurthy et al. [21] further reported that the plasticising effect of water damages the wet coating, and that coating delamination was a possibility with a higher impact velocity. Zehnder et al. [22] even reported a rise in the coating temperature during impact, sometimes exceeding the glass transition temperature of the coating.

Along the same lines of testing requirement comes the steam jet test. Recently, Auerhammer et al. [23] examined the flame pretreated TPO for adhesion performance, combining a fabric-embedded peel test, X-ray photoelectron spectroscopy (XPS), and light microscopy to enable surface characterisation. This research is significant as their result disclosed a significant weakness in the reliability of the very common steam jet test for TPO substrates. Instead, they proposed a semi-quantitative peel strength test for assessing the binding force of the matrix precursor to the substrate. The peel strength test is another common method as per DIN SPEC 91063, where an adhesive tape is placed on the top of the coating, which functions as a flexible joint that can strip off the coating [24]. However, recently, Cho et al. presented a microcap pull-off test assessment for automotive coating adhesion [25]. Herein, a micrometer-thick layer of adhesive material was applied to the divided compartments of the coating substrate, and the detachment of coating layer from the plastic substrate was studied. It was noted that water and organic contaminants reduced the cohesive strength within the adhesion schematics. Having reviewed both the fundamental and testing basics, it will be practical to say that the magnitude of the TPO within the automotive industry will depend, in a large part, on overcoming the technical challenges and roadblocks that are set ahead on its way (Figure 1).

Sustainability aspect

Changes in the bumper/TPO substrate market in the near future might actually be unavoidable. One of the main future aspects is the polymer sustainability criteria [29,30]. From a sustainability point of view, there is a huge number of electric vehicles that are imminent to be on roadways. Concurrently, all of these vehicles will also have new plastic parts in lieu of cost savings due to lightweight materials. An example would be carbon- or glass-fibre-reinforced composites with a bio-based polymer matrix [31]. In addition, biomass fillers are also incorporated to help achieve weight savings, in addition to increasing the overall bio-based content of the composites [32,33]. In such a scenario, with newer and less researched substrates coming into the picture, the coating market will also need to adapt to such a wave and come up with the latest technologies that are easily adaptable in the new era. The substrate market is set to undergo a revolution both in the matter of polymer sustainability and lighter weight materials. In terms of polymer sustainability, it can be a higher bio-based substrate, a recycled substrate of the existing TPO substrates, TPO vitrimers, or an altogether new sustainable substrate.

The use of bioplastics in automotives is an old concept with major automotive manufacturers like BMW, Ford, Audi, Mercedes-Benz, Opel, etc., who are already utilising biocomposites in their vehicles. Majorly, they have been used in door panels and trims, including flax-fibre-reinforced composites from Daimler Chrysler, jute door panels by Mercedes in their ER-Class vehicles, and banana fibre and other bio-based-fibre-reinforced composites. In academia, too, there is much research that has reported on this topic, notably for automotive applications.

Muthalgu et al. [37] recently studied the material and tensile attributes of Kevlar- and date-palm-fibre-reinforced epoxy composites for automotive bumper applications. Bumper design was modeled by CATIA with a bean structure analysed in finite element analysis software (ANYSYS student) via the classical laminate theory. The result with palm- and Kevlar-fibre-reinforced composites were comparable to that of the conventional bumper [37]. Further, to cite a few examples of the research on basic and fundamental biobased substrates for automotive applications, biobased epoxy composites with glass, natural fibre and biomass filler reinforcement were reported by Alice Mija et al. and Soucek et al.

While the former research group concentrated on conventional vegetable/seed-oil-epoxy-based recyclable vitrimers , the latter research group utilised higher reactive functionalised vegetable/seed-oil-based epoxides as a polymer matrix for multiple curing techniques, fabricating reprocessable and recyclable composites. Polyolefin vitrimers themselves are also being researched, with Ahmadi et al. revisiting their basic principles and applications [43]. Vitrimers containing reversible crosslinks are also gaining huge attention in the chemical industry, and the automotive industry can surely be another interested sector.

Though very nascent at the research stage, such vitrimers surely have potential for reversible crosslinks if careful consideration of a balance between solid-like mechanical properties and true recyclability can be achieved. Yet another interesting review was presented by Moghaddam et al. [44], who suggested that such sustainable circular polyolefin efforts were mostly a consequence of global warming and the ubiquitous microplastic challenge looming over the polymer industry. This research team also emphasised the bio-propane and other olefin-based synthesis (Bio-PP) approach as a stepping stone for TPO to maintain its supremacy in the changing market.

It was noted that in addition to bio-based PPs, chemical recycling processes were the best available circular methods, especially pyrolysis and rather catalytic methods like olefin metatheses, which are possible to use even at low temperatures.

One of the ways to avoid landfilling is waste utilisation or recycling. The recipe being a trade secret has been an obstacle, as the exact composition of TPO/PP is unknown to many. The knowledge of physicochemical properties is a major factor in addition to the operating conditions of the recycling process [26]. While the European commission regulation on end-of-life vehicles (ELVs) has established goals for a recyclable system, the United States Department of Energy proposed a plan for a 95% recycling rate target for automobiles, which includes metals, plastics, and other materials. To that extent, researchers have worked with environment aging and oxidation processes [51]. Recently, bumpers from automotive waste were recycled via re-extrusion-injection and it was observed that the removal of micro paint particles is a critical factor for improving the mechanical properties, in addition to non-damp storage conditions [26].

In another case study by Guo et al., the paint removal process was carried out via plastic shot peening followed by the addition of nano-montmorillonite, virgin PP, recycled PP and a compatibiliser. The described system documented the surface oxidation of bumpers as the degradation route via energy-dispersive X-ray spectroscopy analysis. The before-mentioned modified recycled formulation mix exhibited an enhancement in the thermal and mechanical properties of the composites [27]. Thus, there is a need for the modification of the formulation if the recycled PP needs to maintain the same performance. Another example of circular economy research is the efforts documented by Laoutid et al. [28] to valorise recycled tyre rubber for 3D printing TPO and ABS-based composites. They used a non-functionalised styrene–ethylene/butylene–styrene block copolymer (SEBS) as a compatibiliser. The recycled rubber used (15–30wt.%) resulted in successful filament production via fused deposition modeling in 3D printing. It exhibited considerable impact, elongation and compression properties and thus was a promising avenue for recycled TPO rubber SEBS materials.

To cite an example of how major automotive companies are inclining towards this trend, Volvo declared that 25% of plastic in their automobiles will be made from recycled materials by 2025 [52].

READ MORE:

Overview of coatings for PC substrates

It is recognised that a lower fuel consumption is directly linked to the weight of the vehicle and thus, a considerable opportunity lies in the replacement of heavy glass components with polymeric materials. An example would be the headlights and windows, wherein polycarbonate, with its outstanding toughness, light weight, high temperature stability, resistance to LEDs, easy processability, and impact resistance, has come up in the market [53]. The challenges of PC are the lower chemical resistance and poor abrasion/scratch resistance.

PC or its blends with ABS/PMMA/nylon are being used for several lighting applications. Clearly, washing (hand washing or auto wash units) the car, and constant sand/dust in the air result in scratches and a reduction in light transmittance. ABS has its upper hand in being more economical and easier to manufacture compared to PC.

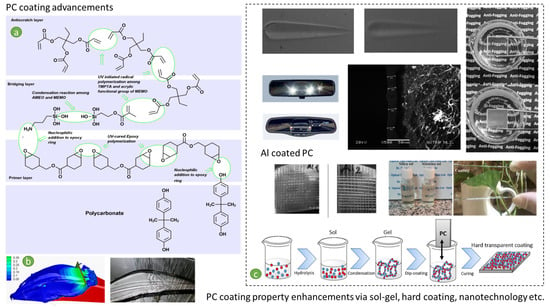

However, the reflector consists of complex structures involving specific plastics and a highly efficient process. In regard to increasing the scratch resistance and hardness, four methods are usually included [55,56]. Such methods include sol–gel and/or hard coatings, coatings applied by either physical or chemical vapour deposition (PVD/CVD), the incorporation of hard nano materials into melted polymer and finally, plasma-enhanced chemical vapor deposition.

All of these methods have been utilised and researched as means of improving the coating properties of PC substrates, mainly anti-scratch properties, anti-glare properties, anti-fogging properties, etc. In terms of the conventional PU coating, there have been recent published reports on the incorporation of branched polycaprolactone (PCL) oligomers into the two components of solventborne polyurethane clear coatings in automotive applications [57]. The effects of the partial substitution of acrylic polyols by tri- and tetra-functional PCL polyols on the adhesion, chemical resistance, thermo-mechanical properties and aesthetic response were analysed. A reduction in Tg promoting a rubbery state, without any reductions in the properties (except slight chemical resistance), and an increase in the wear resistance was reported.

This particular research is of importance to the topic reviewed here because the substrate experimented on was PC/ABS. Let us now look into some of the intricate details of a PC substrate coating and its property enhancement methods.

In terms of achieving a PC substrate coating with a better transmittance, lower refractive index, and a higher water contact angle, the sol–gel method has been particularly popular. It comprises metal alkoxides, silanes, etc. In general, the transmission of PC comes up to 86%, whereas the water contact angle is around 73 [58]. The incorporation of nano fillers has also been reported to be beneficial in increasing the interfacial area and required transparency in clear coats. Several research studies conducted recently attest to this system, along with the capability of a high degree of dispersion of in situ nanoparticles [56]. The metal alkoxide precursor method undergoes condensation and hydrolysis reactions to form a 3D inorganic network wherein hard nanoparticles increase the flexibility, adhesion and fracture toughness. Hard transparent nanohybrid organic–inorganic coatings on PC have also particularly gained attention. Few recent research studies were conducted involving mixing Silicon (Si) and Aluminum (Al) liquid precursors with tetraethyl orthosilicate (TEOS), 3-glycidepropyltriuemthoxysilane (GPTMS), and aluminium tributoxide [61].

The same research study documented that on a pretreated system activated by dielectric barrier discharge and sol–gel coated by dip coating, there was a significant effect of the withdrawal speed and thickness on the mechanical and optical properties of the final coating. However, an optimum condition can be only selected by experimentation [55].

The before-mentioned system achieved a peak transmission of up to 89% and a refractive index of 1.481. Another example of a sol–gel hybrid for the self-cleaning application on PC substrates would be Zirconia (Zr)-based sol–gels. The system utilised dip-coated ZrO2 and SiO2 sol–gel onto PC along with perfluorooctyl trichloro silane (PFTS) for surface modification and achieved a peak transmission of up to 95% at 700nm, and a water contact angle of 113°. Further, the usual cracks that are common in the sol–gel method resulting from micropores in the gel were avoided by using the dry control chemical additives method. Moreover, epoxy functionalised silicones have also been reported to impart better scratch and abrasion resistance due to the formation of polyethylene oxide chains by the polyaddition with aromatic diol [63]. However, one of the key challenges has been the high vacuum and expensive equipment required for the much-needed plasma treatment of PC substrates for surface energy increase. To that extent, dielectric plasma discharge has been reported wherein binary sol–gel thin films were coated, resulting in a lower refractive index coating as compared to silica hybrid coatings [56].

Let us further look at other specific property requirements for PC substrates, including scratch resistance, hardness, anti-fogging, anti-glare properties, etc. (Figure 2).

Polyacrylate-based “hard coatings” (HC) are significant for developing scratch resistance coatings for PMMA/PC substrates. The purpose of an HC in general is to increase the hardness and scratch resistance via a hard coat layer over the substrate surface. An HC can involve an organic oxide, epoxy resin, polyurethane silicone, or polyacrylate, showing plastic deformation on scratches [64,65,66].

Xu et al. reported a study wherein UV-cured acrylates were used as a hard coating for a PMMA/PC substrate, and the properties were tested using the pencil hardness test and progressive normal scratch test. Using finite element modeling (FEM), the research group also noted a relation between the maximum principal stress perpendicular and the direction of the crack propagation. The scratch resistance increased with the increased HC thickness, whereas the maximum principal stresses were decreased, and the crack propagation was delayed. The anti-scratch property can also be achieved with the incorporation of hybrid siloxane–silica sol composites. The challenge, however, is the long cure times and the higher VOC levels.

The use of low VOC radiation cure coatings has been reported as an efficient alternative technique. In such a system reported by Barletta et al., a three-coat system was developed with thin adhesion promoting cycloaliphatic epoxy primer, followed by sol–gel applied to a siloxane bridging layer, and topped by a rough and hard nanocomposite layer based on silica and acrylate [68,69]. All layers were cured by light and exhibited good interlayer adhesion. While such scratch- and mar-resistant systems can be useful for fixed glazing windows or headlamps, the lower abrasion resistance and wear resistance do not make it a good choice for mobile side windows. Polymeric windows have been commercialised by few OEMs, but the lower durability in terms of superior optical transparency is still in question when it comes to polymeric compositions. This is majorly because even optically good and ductile polycarbonates are photolabile and yellow in time with a high propensity to scratches [1].

The requirement of a coating that provides hardness and UV absorption is indeed necessary. Anti-fogging is another area of importance in PC substrate coating. A special hydrophilic/hydrophobic bilayer structure included a base colloidal silica embedded in a cross-linked network of dipentaethritol hexaacrylate (DPHA). A super hydrophilic Tween-20 surfactant, isophorone diisocyanate (coupling agent), and 2-hydroxyethyl methacrylate(monomer) anti-fogging layer was also applied [70]. Though it demonstrated good transparency and anti-fogging properties, it came at the expense of lower hardness and adhesion.

Recently, Sun et al. reported another self-cleaning anti-fogging coating for plasma-treated PC substrates developed from a thin double-layered SiO2/TiO2 structure via pulse layer deposition [9]. Another interesting research study talked about the possible commercialising hurdles of PVD and CVD and proposed a novel three-step process: mild oxidation, self-assembly molecule incorporation, and the co-deposition of nanoparticles [71]. However, the substrates in consideration were ABS, PP, and PMMA, and PC was not included.

Along similar lines, traditional metallic materials are also being replaced by metal-coated plastic in the automotive industry. In that context, sputtering is regarded as a more environmentally friendly method than electrolytic coatings. Conventionally, the chrome plating process was very popular with its protective properties combined with a decorative metallic appearance. However, the presence of harmful hexavalent chromium ions (the cause of lung cancer, skin issues, and respiratory problems) in the chemical bath has forced the industry to explore safer and sustainable alternatives [74].

Europe’s restrictions and the eventual final ban of Chromium VI in coatings happened in 2017 as a result of the regulations set forward by the European Union’s REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). In that context, such an example of a sustainable coating is the decorative chromium coatings on PC substrates using dry coating methods like physical vapour deposition and chemical vapour deposition (PVD/CVD) or thermal spray. PVD processes, known as sputtering, provide protective coatings with good adhesion, controlled morphology, and homogeneity. Further, an issue with chromate plating has been the inability to achieve thicker films (>100nm) in the fear of coating delamination.

In that regard, Ponte et al. [10] recently published a research study wherein a defect-free thicker film (800–1600nm) with and without a base coat was coated onto an initially plasma-treated substrate. With an optimum thickness of 1400nm, an increase in the spectral reflectivity and morphology changes were observed (via scanning electron and atomic force microscopy) in thicker films by virtue of the thermal stress increase and film columnar growth.

This research certainly shows a possibility of achieving a Cr sputter deposition of up to 1400nm with plasma pretreatment on a PC substrate, which would be a revolutionizing change. Further, there are aluminum coatings for ABS/PC substrates reported via the PVD method, and are being tested for reflection efficiency and surface roughness [76]. This particular research group utilised the PVD technique, and using a goniophotometer, the PC coating reflection was noted as a better and more sustainable lighting technology than ABS. Moreover, not just in experimental research, but numerical simulations of flow coating technology processes were also reported for the purpose of lenses in automotive lighting lamps [73]. This research can be particularly useful for avoiding the problems of commonly found “wrinkle” issues (uneven coating layer/bumps due to stagnation) in lieu of weak workability and low controllability within complex 3D structures. A detailed analysis backed by the K-Ɛ turbulence and volume of a fluid multiphase flow model showed that the transition from pulsating to stable flow was noted as a reason for the “wrinkles” phenomenon, and the shape and distribution of the flow vortex were reasons for the “heel” phenomenon.

Applied nanotechnology solutions

Polymer nanocomposites (PNC) for automotive applications is yet another research hotspot due to the possibility of less gas emissions, a low gasoline intake, and moving towards lightweight vehicles. PNCs also impart affordable corrosion resistance and good thermal and mechanical strength. It is reported that PNCs are an emerging technology of the next decade. The nanoscale particles are integrated and distributed within the polymers like polypropylene, polyester, or epoxides and using processes like solution casting, electrodeposition, melt blending, in situ polymerisation, etc.

An example of TPO incorporation would be that of clay nanocomposites providing more dimensional stability and weight reduction. Such substrates were previously commercialised by General Motors R&D and Montell USA. Some other companies like GM and Chevrolet have also implemented PNC polyolefins, especially through the collaboration with LyondellBasell industries. Even though a compatibiliser might be needed in most cases, improved thermal and mechanical properties by virtue of nanoclays (NCs) makes it a worthy successor for conventional TPO composites [79]. Nanoclays, as replacements for conventional fillers like talc or glass fillers, and as reinforcements, are few significant areas of research spearheaded by automotive manufacturers including Chrysler and Mercedes. While polyolefins might compete with the engineering of polymer materials like PC/ABS, a balance of properties are possible with NC-incorporated polyolefins with significant cost savings.

However, the establishment of several factors are required if the fast commercialisation of PNCs is expected. An example would be establishing simple but standardised assessment techniques like IR for clay dispersion determination, treatments for better nanofiller polymer adhesion, the influence of the blend of conventional NC fillers on performance, the affordable and high production of NCs, etc. [77].

Even in polycarbonates, embedding NC into acrylate and polysiloxane paints has been reported [82]. In polycarbonate, carbon nanotubes were incorporated to make nanocomposite coatings using casting and ultrasonic stirring methods to be used as infrared sensors. Further, as we already examined earlier, the incorporation of SiO2, Al2O3, ZrO2, and TiO2 greatly improve the scratch resistance of a transparent coating matrix. The study of nanocomposites have reported that the incorporation of different nanocomposites has the ability to enhance very specific properties: (1) TiO2, SiO2, and Al2O3 nanocomposites enhance the abrasion resistance; (2) TiO2 and SiO2enhance the UV resistance; (3) TiO2 nanoparticles provide easy-to-clean features; and (4) TiO2 and ZnO enhance anti-fogging UV resistance [53,82].

Anti-glare technologies also utilise the interdisciplinary advancements in the polymer field with dichromic technology. An example includes a modified ethanolic suspension of dispersed crystalline indium nanoparticles with hydrolyzed silanes [83]. Self-cleaning on the other hand, utilises nanometric oleophobic and hydrophobic coatings via the chemical vapor deposition (CVD) process [84]. The mirror surface and coating are chemically bound from the sides of the anchor groups, and a hydrophobic surface is created by the chemical groups on the opposite side of the substrate.

Autonomous driving and driver assistance systems with highly automated driving functions have brought in a much-needed future aspect for TPO bumpers [6]. This emergence would mean sensor technology incorporation into the back of the bumper without affecting the vehicle design. To that extent, the relative permittivity of the coating layer plays a vital role. The higher permittivity of coatings could lead to a lower radar performance. Apart from the earlier reported research [85,86], Winter et al. recently published a method to find the relative permittivity of multilayer automotive coatings for 76–77 GHz radars [87]. It involved a vector network analyser (VNA) with corrugated horn antennas and suggested an all-in-one quasi-optical free-space measurement solution. Herein, commercially available measurement devices were utilised, and high precision values for three-layer coatings were reported, except with the water-based base coat, which exhibited viscous behavior. However, PC was used as the substrate as opposed to PP or TPO due to the low precision of PP by virtue of its less homogeneous dielectric behaviour.

In the era of advanced polymers, low-temperature cure systems aimed at heat-sensitive substrates have come up as one of the high-demand materials. The two-component (2K) polyurethane coatings first enabled the lower curing temperature in plastic substates coupled with a higher flexibility and abrasion resistance. Herein, future opportunities arise with the emergence of new UV-curing systems. There has been a plethora of research carried out on UV-curing systems in academia in recent years. Some of the common systems are free radical and cationic curing systems with light sources like mercury, LEDs, lasers, etc.

However, though an academia-oriented fundamental structure–property correlation study is a good strategy to devout attention to creating low-temperature cure coatings, it is time to work collaboratively with coating companies and develop novel technologies in order to make it competitive with the existing commercial products.

Several companies like Allnex, Allied Photochemical, PPG, AkzoNobel, Dymax, etc., are actively expanding their UV-curable technologies. No UV-cured coatings on TPO substrates have been reported yet as per the author’s knowledge and the reported literature. However, UV-cured coatings for PC substrates were recently reported by Park et al., utilising cycloaliphatic-epoxy-derivative-based cationic ring-opening polymerisation monomers.

The dark cure ability of the cationic photopolymerisation was also beneficial to enhance the performance properties via better crosslink network. Low-temperature curing for heat-sensitive substrates is an emerging technology, and many questions about its different product performance need to be answered if we are aiming for the successful technological transfer from the numerous research works in academia. Among the new advancements, low-temperature curable novel UV powder coatings surely have the potential to be gamechangers. Will these alternative materials have any negative impacts on the product’s end performance? The new advancements surely require extensive research on the technology front.

Among the radical changes in the metallisation of plastic substrates, the bio-inspired green approach by using dopamine (DA) from mussel proteins as an adhesion promoter is a typical example. Earlier, it was reported to be used in membranes and biomedical applications, but herein, these UV-curable DA systems were plasma treated initially. Reductions in energy, hazardous materials, and the manufacture reject rate with a good metal–plastic interphase adhesion (3.7 N/mm2) were reported. The key functional element is the byssus filament present in DA that can adhere to both organic and inorganic surfaces while withstanding higher shear forces. As a basis of electroless metallisation with polyethylene substrates, the applicability of such polydopamine (PDA) layers were appreciable. Even if it is not a topic of interest for this review, it is important to note that plating on ABS is also of significance, with much recent published research on the greener electrochemical plating of ABS, including aluminium platings, micro-nanotexturing, etc. Furthermore, there were coatings recently reported for elastomeric substrates via atomic layer deposition with TiO2 and diamond-like carbon (DLC) films.

In this review, a general outlook of the past and current advancements in two of the main exterior automotive plastic coatings are summarised. It is a topic that is of major interest in the scientific community, and quantitative and scientific tools are clearly needed to facilitate and gauge its effectiveness. How each of the new proposed systems influence the key properties of the final product performance needs to be benchmarked after meticulous study.

It is vital that in the name of inspiring sustainable practices, we do not create inferior products, as vehicle safety features are of utmost importance. Life cycle and economic feasibility evaluation is also necessary for integration into global processes. There are standards and regulations that exist around automotive exterior coatings and can be easily carried out by academic and research institutions alike. Such standardised test-based research would certainly reduce the gap and time required for technology transfer. If we look at some of the trends, challenges, and limitations, they include (1) the extension of PC substrates as alternate onto more conventional glass substrates, (2) the commercialisation of water-based and UV-cured systems, (3) the emergence of low-temperature cure coatings, and finally, (4) the lower weight sustainable and biobased plastic substrates and coatings, not just to cater to electric cars, but to improve the overall sustainability and carbon footprint of the entire automotive industry.

Nevertheless, to bridge the gap between the actual commercial integration and some of the basic material innovations described here, interdisciplinary studies are mandatory. In that context, it is highly beneficial if the foundational guidelines from industry collaboration becomes a routine way for application-based academia research to make the commercialisation of windows realistic.

The authors believe that the exterior automotive coatings section is sure to have a strategical need for new developments, keeping in mind the new and lightweight substrate solutions associated with EV revolution. The emergence of new and improved sustainable plastic is going to be pivotal, especially for electric vehicles, as the efficiency and profitability are enhanced with less bulky materials. Breakthroughs are needed to withstand the requirements of the emerging market in lieu of impending change. New technology-based products at an industrial scale can be developed only by more comprehensive and systemic research. Subsidies for novel low-temperature curing methods, especially with sustainable and renewable systems, can also be provided by the government. We hope that this review stimulates further development in this area and proves to be useful in the understanding of the potential commercialization opportunities of exterior plastic substrate coatings.Future perspectives