More news

- View from the UK: Navigating chemical policy and sustainability

- Focus on adhesives: Unveiling unbreakable bonds – Testing redefines physical strengt...

- Focus on adhesives: Henkel and Covestro collaborate for sustainability of engineered wood ...

- Advances in construction chemical technology: What’s new in 2024?

- Focus on sustainability: PPCJ speaks to BASF Dispersions Asia Pacific about its holistic a...

Artur Palasz, Spektrochem, discusses how to prevent flash rust when formulating waterborne paints that come into contact with metal elements

Waterborne paints account for the vast majority of the coatings market in the US, not only in decorative architectural applications (painting buildings, residences, etc.), but also in industrial and semi-industrial applications on a variety of substrates ranging from wood, through plastics to metal. Direct-to-metal (DTM) paints are also a rapidly growing group of coatings, especially based on one-component waterborne acrylic paints for DIY applications. It is normal for such paints to use corrosion inhibitors for long-term protection, e.g. strontium zinc phosphosilicate selected for the formulation on the basis of tests in the salt spray chamber and condensation chamber, allow for the appropriate corrosivity classes according to the requirements of ISO 12944.

Waterborne paints naturally contain water, which must evaporate from the coating in order for it to form on the substrate and for the long-term corrosion inhibitor to work. Until the coating dries, the metal substrate is exposed to water and various substances dissolved in it, which can cause the so-called flash rust to appear during drying (Figure 1).

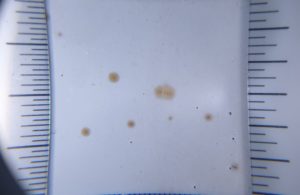

Another problem may be packing water-based paints into metal cans, which is quite common practice, or even if the cans are plastic, the lid and ring it is pressed into is often metal, as is found in both quart and gallon cans. The inner surfaces of the cans and the lids are usually resin-covered, however, the influence of the water environment in the long-term storage of paints in the can (even up to 5 years) may cause corrosion to appear inside the can, contaminating the paint (Figure 2).

Figure 1. Flash rust stains on the dried coating

Figure 2. Corrosion inside the waterborne paint can

"The formation of flash rust is caused by the slow drying process of the paint on the substrate and the reaction of oxygen dissolved in the paint. This process is also intensified by high air humidity during the drying of paints, as well as various additives present in them that can additionally cause corrosion, such as dispersants."

Flash rust and architectural waterborne paints

The problem of flash rust is not limited to waterborne paints on metal. Also in architectural paints for painting walls and ceilings, there may be a case where the base will contain nail heads, staples or other metal elements, which together with the wall will be evenly covered with latex paint. Then, local rusty spots are formed in places where such metal elements were present. Often, water-based paints are also formulated as universal for a variety of substrates, from mineral substrates on walls to wood substrates as well as metal substrates. Such a wide range of applications can be found most often in waterborne alkyd paints, but also in many cases in waterborne acrylic paints. Then the same paint can be used to paint the walls in the corridor, wooden railings or metal flashings. This is why in such formulations it is important to take into account the selection of a flash rust inhibitor, as in the formulations of latex paints, an additional fungicide is used to protect the coatings against the development of moulds, although not all of them are dedicated to wood, as in the case of latex paints, which are primarily dedicated to metal. Protecting metal cans from corrosion is equally important as it affects the shelf-life of the paint and its usability once the can has been opened.

Protecting the cans is also important, as the use of paint involves frequent opening and closing of the can, which causes the lid to rub against the ring and the protective coating on the lid is damaged. Such damage to the area and contact of the paint directly with the metal wall of the can may cause corrosion to develop when the can is closed between painting. In addition, wiping the brush against the edge of the can also causes the waterborne paint to come into contact with the metal elements on the ring, hence care for a well-chosen flash rust inhibitor is doubly important.

READ MORE:

View from the US: Don’t look now, but PFAS is EVERYWHERE!

Binder transfer in paint and coatings

Focus on industrial: The hydropower industry and epoxy coatings

The formation of flash rust is caused by the slow drying process of the paint on the substrate and the reaction of oxygen dissolved in the paint. This process is also intensified by high air humidity during the drying of paints, as well as various additives present in them that can additionally cause corrosion, such as dispersants. Regardless of whether we are talking about waterborne paints based on acrylic or vinyl-acrylic polymer emulsions, in which the coating is formed by coalescence, or waterborne alkyds, in which the coating is formed by the addition of oxygen, the initial drying process takes place in each from cases before water evaporation.

The drying time depends on the temperature and humidity and as the temperature decreases and the humidity increases, the drying time is extended and at the same time, the time in which the water is in contact with the metal or other substrate with metal elements, e.g. nail heads, is extended. Purposeful treatments of the formulator in the form of extending the open time of paints using OTE additives (open time extenders) cause that the contact of the wet coating, and therefore water, with the substrate can last from several minutes to even several hours. One should not forget about the pH of the paint, which is also important for facilitating corrosion processes and, together with lowering the pH, favours the faster formation of flash rust. All this makes flash rust inhibitors a must-have item in formulations, also for standard waterborne latex or waterborne alkyd paints.

Experimental

In order to check how the flash rust inhibitors work and how effective they are in the formulations, application studies were carried out in the wood & trim PVC 20% formulation based on self-crosslinking acrylic emulsion. Two liquid flash rust inhibitors were tested at a dose of 1.5% by weight in the total formulation:

- Flash rust inhibitor #1 based on salts, nitrate free

- Flash rust inhibitor #2 based on salts containing sodium nitrite

The dosage was set at the same level due to the same content of active solids ca. 20 % of each of the flash rust inhibitors. The wood & trim paint formulation was deliberately prepared for testing to test the effectiveness of inhibitors in a formulation not dedicated to metal.

Scope of test

Tests were carried out to assess the effectiveness of flash rust inhibitors in terms of:

- Protection of the steel substrate against flash rust at the time of application and drying

- Protection of cans during paint storage and when opened during painting

- Influence on other parameters that inhibitors can affect in the paint

The scope of the tests included standardised and in-house development test procedures presented in Table 1.

| Table 1. Scope of test methods | |||

| Test | Standard | Apparatus | Details |

| Flash rust efficiency | In-house procedure | Steel panels, lab spatula, 10x magnifying glass | Spreading by spatula on steel panel with different coating thickness |

| Can protection | In-house procedure

Modified ASTM D1849 |

Cans not sealed with resin, Thumler’s mill, lab oven, paint brush | Storage stability test for corrosion inside the can |

| Impact on viscosity | ASTM D562 | Digital Stormer Viscometer | Measurement

after 7 days |

Test results

The test results are discussed and interpreted below.

Effectiveness of flash rust prevention

Figure 3 shows pictures of coatings after spatula application to steel panels. The application with a spatula was intended to obtain spreading with different thicknesses of layers because, as you know, flash rust appears mainly in thinner layers, although this is not a rule either. The impact on the steel substrate and the formation of flash rust stains depends on the intensity of their occurrence on the composition of the paint and its properties. Drying time is of paramount importance here, because the longer the coating stays wet on the substrate, the longer it takes to react with it. The pH value of paints is also important here, as well as its components such as polymer dispersion, dispersing additives, defoamers, thickeners, etc.

Figure 3. Comparison of the effectiveness of two flash rust inhibitors against a control sample

The coating of the control paint shows stains and streaks of flash rust visible to the naked eye, which clearly proves the need to use an appropriate additive to protect steel substrates when applying this paint to elements present in wood, e.g. nail heads. Paint with Inhibitor #1 (nitrate free) shows localised but visible staining. This proves that the activity of the tested inhibitor is achieved, however, its dose probably needs to be increased to ensure proper protection of the steel substrate. The coating with inhibitor #2 (containing nitrates) shows a complete absence of flash rust spots.

The evaluations carried out in this way show that nitrate free rust inhibitors are an alternative to their conventional counterparts used so far, however, their selection must be supported by application tests to determine the appropriate dose, as the tested example is the best proof that the 1:1 conversion did not give satisfactory effectiveness in the field of protection of the steel substrate against flash rust.

Can protection

Prepared paints in liquid form were also tested. The first of the tests was to assess the effectiveness of protecting the cans against corrosion inside during paint storage. For this purpose, the paint samples were deliberately placed in cans not sealed with resin, in which the paint is in direct contact with the walls of the can. For uniform coverage of the inside of the cans, the test paints were mixed in the cans for 10min on a Thumler’s roller-mill (Figure 4) and then placed in oven at 52°C (125°F) to increase the vapour pressure of water and other volatile components under the lid causing their additional penetration between the can ring and the lid.

Figure 4. Thumler’s roller-mill preparing paints to be placed in the oven

After removing the can, it was allowed to cool at 23°C (73.5°F) and then the degree of corrosion of the lid, walls inside the can and contamination of the paint with rust was assessed.

The results are shown in Figure 5 and Figure 6. As can be seen, the control paint shows significant traces of rust on the lid as well as on the ring of the can. There is also visible contamination of the paint in the form of a slight rusty colour and individual rust particles that have fallen into the paint. Paints with both flash rust inhibitors show no signs of rust inside the cans.

This proves good effectiveness in protecting cans when water-based paints are stored in them. Such tests are carried out in the Spektrochem laboratory to determine also long-term storage stability and can protection under accelerated conditions.

Figure 5. Cans with test paints and visible corrosion of the control paint can

Figure 6. Visible light orange-rust colour of the control paint and white uncontaminated test paints with inhibitors

Impact on viscosity

When selecting additives such as flash rust inhibitors, it is also very important to check to what extent they affect paint parameters other than those for which the additive is usually tested. One such parameter is viscosity. Determining how much a flash rust inhibitor affects viscosity changes provides formulators with information on the need to take into account changes in rheological additives to ensure the desired rheological properties. In the case of the tested paints, it can be seen that flash rust inhibitor #1 has an effect on the change in viscosity in the mid-shear forces area, determined by the Stormer viscometer measurement and expressed in KU (Krebs Units). The control paint has a viscosity of 84 KU after 7 days of preparation, and with flash rust inhibitors it is suitable: with #1 inhibitor – 95 KU, and with #2 inhibitor – 84 KU [readings presented in Figure 7]. As you can see, the flash rust #1 inhibitor increases the viscosity in relation to the control paint, which is valuable information for the R&D department regarding further viscosity adjustments.

Figure 7. The results of paint viscosity measurements with the Stormer viscometer

Summary

Corrosion inhibitors are extremely important additives, and as the application studies presented in this article show, they are also important in paints not intended for metal. Their importance is particularly important in waterborne paints packed in metal cans and despite their resin sealed, such a flash rust inhibitor additive should be included in the formulation to ensure long-term storage of the paint. Application studies showing the effectiveness of doses of flash rust inhibitors, in turn, provide extremely valuable data showing how to easily and quickly use a given additive for a formulator aimed, for example, at changing a nitrate-containing inhibitor to nitrate-free.

Providing additional characteristics of the effect of a given flash rust inhibitor and its dose on viscosity, potential changes in the gloss of the coating or other properties is just an added value to application studies to facilitate the formulation of recipes, not only for metal paints, but also for all kinds of water-based paints that may come into contact with steel surfaces (e.g. inside cans, metal elements protruding from painted substrates or metal elements of painting tools).

Author details

Artur Palasz, Ph.D., SPEKTROCHEM – Technical Center of Raw Materials for Architectural Paints, Poland

E-mail: artur.palasz@spektrochem.pl