More news

- Innovative coatings mitigate effects of deepening climate change

- View from the UK: Navigating chemical policy and sustainability

- Focus on adhesives: Unveiling unbreakable bonds – Testing redefines physical strengt...

- Focus on adhesives: Henkel and Covestro collaborate for sustainability of engineered wood ...

- Advances in construction chemical technology: What’s new in 2024?

Dr. Claudia Schirp, Scientist at Fraunhofer Institute for Wood Research, discusses the Institute’s latest research on bio-based wood coatings with flame retardancy

Building with the natural and renewable raw material, wood, is very popular. The wood should have effective fire protection in the required applications. The aim here is to use a coating that is permanently resistant to the effects of weathering and is based on renewable, bio-based raw materials.

Motivation

Wood is increasingly used in the visible areas of interior design, as the look, feel, acoustics and insulating effect of this natural material are appreciated. The wood is protected by coatings, preferably transparent coatings, in order to preserve the look of the wood. However, most of the coatings on the market to date consist mainly of petro-based raw materials. Especially in combination with wood as a substrate, it is desirable from the point of view of coating users and manufacturers to increase the content of bio-based raw materials. In addition, fire protection requirements are playing an increasingly important role, especially when used in public spaces. If constructive solutions are used for fire protection, the wood often remains invisible as the wood is covered with inorganic materials such as plaster or cement. The use of transparent coatings offers the advantage that the wood or wood-based materials remain visible. Most of the flame retardants available on the market are also not made from renewable raw materials. Common solutions are based on intumescent coatings. The use of inorganic flame retardants, which are usually based on salts, can sometimes lead to unsightly efflorescence and ultimately to a loss of fire protection performance. The Fraunhofer WKI is conducting intensive research with numerous partners in the field of bio-based wood coatings with a permanent fire protection effect.

New bio-based binders

The main component of a coating is the binder. Acrylics and polyurethanes account for the largest share of the market. Although a great deal of research has already been carried out into providing bio-based monomers, most products are based on petrochemical raw materials. In the case of a fire protection coating, the binder must also be optimally matched to the flame retardant to provide sufficient fire protection.

Image caption: Bio-based Monomer based on saccharides

The Fraunhofer WKI specialises in the development of bio-based wood coatings with various functions, including flame retardancy. The coatings are to be used both indoors and outdoors and fulfil the technical requirements. Particular attention is paid to the ability to absorb and release water. This is important for a pleasant indoor climate. In outdoor areas, good water vapour permeability is desirable with simultaneous protection against rain and leaching of ingredients. The challenge is to combine good weather protection with durable flame retardancy. In terms of chemical, abrasion and scratch resistance, the coating should be competitive with commercially available products for furniture and interior design, as well as being low-emission or emission-free.

Various new bio-based monomers are being used to achieve application-typical properties for both wood façades and furniture coatings. Sugar-based monomers in particular have already been used successfully. These are being optimised in terms of their compatibility with flame retardants. One of the new bio-based monomers used is based on glucose, a simple sugar. The ring structure makes it possible to increase the hardness of the coating film and thus achieve high abrasion and scratch resistance for furniture coatings, for example. Monomers that produce hard polymers through polymerisation are not yet well represented in the range of bio-based monomers. This also poses new challenges for formulation, as the coordination of the additives has to be adapted.

READ MORE:

A bio-based alternative to TiO2: Finnish startup company focuses on birch bark

To date, acrylates with a sugar monomer content of 50% have been produced in emulsion. The films are transparent and show good tensile strength. By replacing other monomers, a bio content of over 60% would be possible. In the case of polyurethane dispersions, 17% of a sugar alcohol could be used to date. The potential here is over 60%. Both products are compatible with proven intumescent mixtures.

The challenge with fire protection coatings is that the flame retardants are washed out, so that the effect of the coating is greatly reduced by weathering or use. Commercially available fire protection coatings use a top coat to protect against washout. In order to be able to avoid a top coat and still minimise leaching, we are pursuing the solution of not only using bio-based flame retardants as an additive, but also chemically bonded to the polymer. This involves using new groups of substances that are more effective and therefore, need to be used in much smaller quantities in coatings in order to achieve comparable results to conventional fire protection coatings.

Fire protection

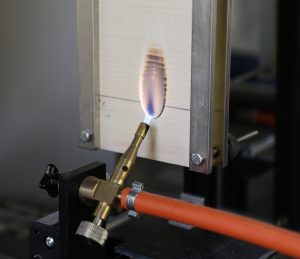

The fire behaviour of the developed coatings is determined for the first orientating test series by a single source flame test according to DIN EN ISO 11925-2. For further characterisation of the fire behaviour, the developed materials are examined using a cone calorimeter. The main parameters determined here include the heat release rate, mass losses, smoke development and ignition time. In combination with measurements of thermal stability, the flame-retardant mechanism can be analysed and the fire behaviour optimised by adjusting the binder.\

Image caption: Single source flame test on a coated wooden surface

Outlook

The new bio-based monomers used at the WKI offer the possibility of developing customised coatings for various applications. The material properties can be controlled and predicted through different compositions of the monomers, thus expanding the property portfolio of the bio-based binders. Functionalities such as flame retardancy, biocidal effect and hydrophobicity can be integrated into the binder by adapting the monomers so that additional additives are ideally no longer necessary. This creates bio-based, low-emission and durable coatings for the natural material wood, which are very well suited for applications in timber construction.

Author information

Dr. Claudia Schirp, Scientist at Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut, Braunschweig

Email: claudia.schirp@wki.fraunhofer.de

All images (except main image) copyright: © Foto Fraunhofer WKI | Manuela Lingnau