More news

- View from the UK: Navigating chemical policy and sustainability

- Focus on adhesives: Unveiling unbreakable bonds – Testing redefines physical strengt...

- Focus on adhesives: Henkel and Covestro collaborate for sustainability of engineered wood ...

- Advances in construction chemical technology: What’s new in 2024?

- Focus on sustainability: PPCJ speaks to BASF Dispersions Asia Pacific about its holistic a...

Lichao Sun, Lin Yuan, Fei Wang, Nirmit Khanna, Parag Gaikwad, Shijie Qiao, Junjie Ren, Andry Darmadjie discuss the technical background behind BASF’s newly launched IO-Hybrid Technology

In today’s dynamic market, paint companies face a significant challenge of creating more value in their paint formulations. This challenge requires delivering more consumer benefits to meet the market needs, while continuing to increase product performance. With the increasing demand for eco-friendly coatings, paint companies must also ensure that their formulations are sustainable and environmentally friendly.

To address these challenges, paint companies are investing in research and development to create innovative formulations that offer multiple benefits to consumers. These benefits may include improved durability, resistance to stains, reduced VOC, anti-microbial properties, in-can biocide free, and more.

In addition to formulating coatings with multiple benefits, paint companies are also focusing on improving the application process for their customers. This includes developing coatings that are easy to apply and offer higher coverage, requiring fewer coats to achieve the desired finish. By improving the application process, paint companies can enhance the user experience and increase customer satisfaction.

Overall, paint companies must continue to innovate and evolve their products to meet the ever-changing demands of the market. By delivering more consumer benefits and improving product performance, paint companies can differentiate themselves and maintain a competitive edge.

Our latest innovation based on IO-Hybrid Technology is exciting news for the paint industry.

What is IO-Hybrid Technology?

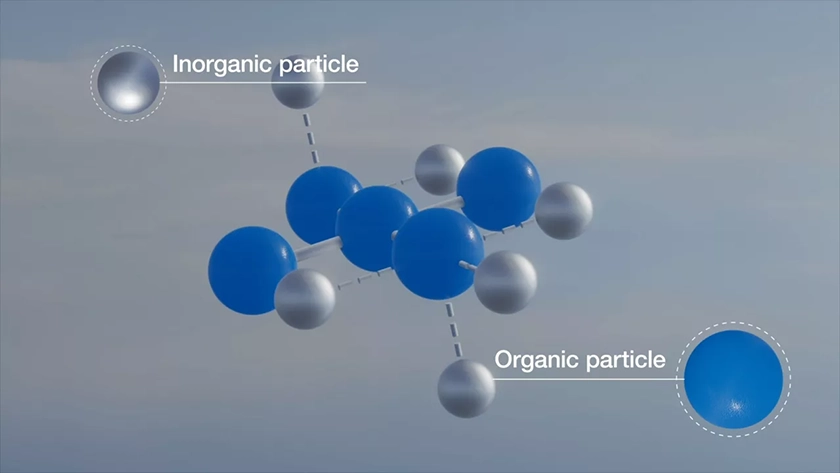

IO-Hybrid Technology is BASF’s patented technology, designed to empower paint formulations to create coatings that provide superior performance and sustainability. By merging organic and inorganic nanoparticles to create a unique matrix, this technology unlocks a range of properties and benefits that are highly desirable for architectural coatings.

With IO-Hybrid Technology, paint formulations deliver exceptional hiding performance. This means that the paint provides excellent coverage and opacity, allowing for a more even and consistent finish. The ability to hide underlying colours or imperfections is highly desirable for achieving the desired aesthetic result. It also offers antimicrobial features and biocide-free properties, which are essential for protecting people’s health and creating a safer living environment. This is particularly important in environments where cleanliness and hygiene are crucial, such as healthcare facilities, schools, or residential spaces.

Furthermore, IO-Hybrid Technology offers a sustainable solution that meets the increasing demand for eco-friendly coatings. By reducing the environmental impact of coatings, paint formulations that incorporate this technology can help companies achieve their sustainability goals and meet regulatory requirements.

Overall, IO-Hybrid Technology provides paint formulations with a comprehensive solution to create coatings that offer superior performance and sustainability. By leveraging this innovative technology, paint companies can differentiate themselves in the market and provide customers with high-quality and eco-friendly coatings that meet their specific requirements.

The film structure characteristics of paint prepared using IO-Hybrid Technology dispersion

The IO-Hybrid Technology dispersion creates a distinctive film structure in the paint film. When compared to regular high PVC paint, the paint film prepared using IO-Hybrid Technology exhibits a higher density of micropores, and these micropores are alkaline. The increased micropore density was confirmed through mercury porosimetry, as illustrated in Figure 1.

The PVC of the testing paint formulation used for this test is around 83%. In Figure 1, the micropore density and pore size distribution of a paint film prepared by IO-Hybrid Technology dispersion Acronal® EDGE 7073 were compared to a standard styrene acrylate dispersion (SA), a commercially available styrene acrylate dispersion with varying levels of TiO2, and a commercial interior paint with a similar high PVC. It demonstrates that the micropore density of Acronal® EDGE 7073 was approximately twice that of all the other comparison paints at a pore size of 0.8-1 μm, while the micropore densities of all the comparison paints were relatively similar. The higher micropore density in Acronal® EDGE 7073 enhances opacity of the paint film.

Opacity in a high PVC paint film can be achieved through the combined effects of TiO2 and micropores. TiO2, a widely used white pigment, possesses excellent opacifying properties due to its high refractive index and ability to scatter light. Moreover, the presence of micropores within the paint film can contribute to its opacity by refractive index difference between air and the polymer matrix. The higher micropore density achieved through IO-Hybrid Technology dispersion resulted in improved opacity and provided the added benefit of reducing the amount of TiO2required in the paint formulation, leading to TiO2 savings. The results of these findings will be discussed in Part 3.

Figure 1. Mercury porosimetry results

Apart from the higher micropore density, another notable feature of IO-Hybrid Technology is its alkalinity. A preliminary pH test of the micropores in the paint film was conducted by placing a water droplet on the film and using pH paper to determine the pH range of the water. In comparison to the green colour and pH range of 7-8 observed in the normal paint (Figure 2b) after the test, the water droplet on the paint film prepared using Acronal® EDGE 7073 exhibited a pH range of 10-12.

Figure 2. Rough pH tests were conducted on a) a 60-day-old paint film prepared by Acronal® EDGE 7073, and b) a 30-day-old normal paint film prepared by styrene acrylate dispersion.

Antimicrobial features giving your home a better protection

One of the key properties of IO-Hybrid Technology is its antimicrobial nature. Paints based on Acronal® EDGE 7073 exhibit excellent resistance against viruses and bacteria commonly found in everyday environments. This antimicrobial property provides increased protection for families against the outbreak of diseases such as Influenza and hand, foot and mouth diseases. The test results demonstrating the antimicrobial effectiveness are presented in Table 1.

Chinese standard of anti-virus coating requires a 24hr efficacy assessment and the tested paint film demonstrated a >99% effectiveness against all tested viruses and bacteria, including EV71 (a representative non-enveloped virus known for its resistance to deactivation) and Human Coronavirus 229E (an additional test conducted). In addition to the 24hr efficacy, a 2hr efficacy test was performed on EV71 and H3N2 to evaluate the speed of virus deactivation. The paint film exhibited high efficacy against both viruses at 2hr.

Durability testing of the antimicrobial property assessed how long the effect would last on the wall. In this test, the paint films underwent accelerated aging conditions prior to the antimicrobial tests. The efficacy after accelerated aging was shown in Table 1 and exceeded the requirements specified in the standard. Furthermore, EV71 was selected as a representative virus due to its challenging nature, and the antimicrobial durability after real aging was evaluated by storing the paint film at room temperature for 1 year. The paint film demonstrated a >99% deactivating effect against EV71 even after the one-year aging period.

Table 1. Antimicrobial results of paint film prepared by Acronal® EDGE 7073

| Efficacy (24h) | Efficacy (2h) | Durability* | Efficacy after 1 year** | |

| EV71 | 99.11% | 99% | 97.73% | 99.02% |

| H3N2 | >99.93 % | 98.33% | >99.93% | Not tested |

| Escherichia coli | >99.99% | Not tested | >99.99% | Not tested |

| Staphylococcus aureus | >99.99% | Not tested | >99.99% | Not tested |

| Human coronavirus 229E | 99.4% | Not tested | Not tested | Not tested |

*Durability – UV exposure at 30w 253.7 wavelength condition 100hrs

**Efficacy after 1 year storage of the paint film

The proposed mechanism behind the antimicrobial property of IO-Hybrid Technology is attributed to the presence of enriched alkaline micropores. The higher density of micropores, particularly those around 1μm in size as indicated by the curve in Figure 1, is significantly larger than the typical size of viruses. Within these micropores, an alkaline micro-environment is created, which effectively deactivates the proteins of viruses or bacteria that come into contact with the wall and reside within the micropores. As a result, the viruses or bacteria are deactivated or killed.

Superior performance in like-for-like recipe

As discussed in Part 1, the utilisation of Acronal® EDGE 7073 in paint formulations enriches the micropores within the paint film and leads to increased opacity while using the same quantity of titanium dioxide (TiO2). By reducing the reliance on ingredients that require energy-intensive production, paint companies can enhance their environmental sustainability within the industry.

Figure 3 illustrates the opacity improvement achieved with Acronal® EDGE 7073, highlighting the potential for TiO2reduction in paint formulations. Acronal® EDGE 7073 achieved contrast ratio of 0.927 in the paint with 3% TiO2, while a commercial styrene acrylate dispersion only achieved 0.893. This finding was further supported by the visual appearance on the black substrate, as depicted in the upper part of Figure 3a.

To explore the opacity performance of Acronal® EDGE 7073 across various TiO2 and dispersion dosages, the curves in Figure 3b were generated. The results showcased the exceptional opacity performance across high PVC paints, catering to the mid-tier and general-purpose market segments.

Figure 3. Opacity comparison of paint films prepared by a) Acronal® EDGE 7073 and a commercial styrene acrylate dispersion in the same paint formulation; and b) different TiO2 dosage with a 10% or 15% dispersion dosage.

Figure 3. Opacity comparison of paint films prepared by a) Acronal® EDGE 7073 and a commercial styrene acrylate dispersion in the same paint formulation; and b) different TiO2 dosage with a 10% or 15% dispersion dosage.

Normally wet scrub resistance and other paint properties will drop with increasing of PVC and micropores in the paint. However, BASF uncompromising approach to product innovation has led to deliver exceptional product quality along with higher micropores, such as wet scrub resistance and low-temperature film-forming performance to meet the market needs.

Figure 4 displays the results of GB wet scrub resistance, low-temperature film formation, Free-Thaw stability, storage stability and alkaline resistance tests. Acronal® EDGE 7073 demonstrated better scrub resistance and low-temperature film formation in terms of chalking when compared to the market benchmark dispersion, which was a styrene acrylate dispersion. The table in Figure 4 also highlights that the high PVC paint prepared using Acronal® EDGE 7073 passed other key performance tests required by the GB standard.

Figure 4. GB wet scrub resistance, low temperature film formation and other application properties of high PVC paint prepared by Acronal® EDGE 7073.

To gain a better understanding of the application benefits of IO-Hybrid Technology, the potential for TiO2 savings were examined. Firstly, in the paint formulation which contained 20% & 10% dispersion, opacity was compared between Acronal® EDGE 7073 and normal SA dispersion at different TiO2 dosage (as shown in Figure 5). The comparable visual appearance and contrast ratio suggest that a TiO2 saving of 50% is achievable with Acronal® EDGE 7073 in both 20% and 10% dispersion dosage formulation.

Figure 5. Opacity comparison of general styrene acrylate dispersion and Acronal® EDGE 7073 with different TiO2dosage in a) 20% dispersion dosage formulation and b) 10% dispersion dosage formulation.

Secondly, Acronal® EDGE 7073 was compared with a commercial VAM dispersion. As shown in Figure 6a, comparable dry opacity was obtained even there were 40% TiO2 reduction in paint with Acronal® EDGE 7073. Washability was also compared in Figure 6b. Scrub cycles and dispersion dosage were listed on Figure 6b. In terms of washability, 20% dispersion reduction is possible compared to VAM dispersion.

Figure 6. Comparison of Acronal® EDGE 7073 and a commercial VAM dispersion. a) Dry opacity; b) Washability of 8% / 10% VAM dispersion and 8% Acronal® EDGE 7073.

Innovation for safer formulation

The absence of biocide in biocide-free paints has garnered significant attention due to stricter regulations. The alkaline conditions present in Acronal® EDGE 7073 and its paint create an unfavourable environment for the growth of bacteria and fungi. As depicted in the figure below, the pH level of Acronal® EDGE 7073 and its paint measures approximately 11, effectively preventing the growth of most bacteria and fungi during storage. Consequently, the storage of Acronal® EDGE 7073 and its paint does not require the use of biocides. To validate these assertions, challenge tests were conducted on both the dispersion and paint, without the presence of biocides. Regardless of pre-treatment (such as heat storage for one week at 50°C), both the dispersion and paint successfully passed the challenge test for at least three rounds without the need for biocides.

Conclusion

IO-Hybrid Technology offers the following benefits that make it an attractive option for paint formulations:

Superior Performance: Your product offers improved hiding power and scrub resistance, resulting in a high-quality finish. The enhanced hiding power ensures better coverage and opacity, while the improved scrub resistance allows for easy maintenance and longevity of the coating.

Empowered Formulation: By optimising raw material usage, your product enables paint formulations to achieve superior performance while maximising resource efficiency. This empowers paint manufacturers to create coatings that are both effective and sustainable.

Stronger Protection: The effective antimicrobial functionalities of your product provide stronger protection against viruses and bacteria. This feature is crucial for maintaining a hygienic environment and reducing the risk of contamination on painted surfaces.

Safer Recipe: The elimination of in-can biocide in your product provides a safer recipe without compromising on storability. This ensures a healthier environment and addresses concerns related to the use of biocides in coatings.

These key benefits position your product as a compelling choice for customers in the paint and coatings industry. By offering stronger protection, superior performance, an empowered formulation and a safer recipe, your product meets market demands while prioritising health, sustainability, and quality.

For more information, visit the IO-Hybrid Technology page