More news

- PPG reports results for Q1, 2024

- FEICA 2024 open for registration

- Vattenfall and BASF sign purchase agreement for 49% of Germany’s Nordlicht offshore wind...

- AkzoNobel delivers continued volume growth and margin expansion in both Paints and Coating...

- PPG appoints Pascal Tisseyre as Vice President, government affairs, Europe, Middle East an...

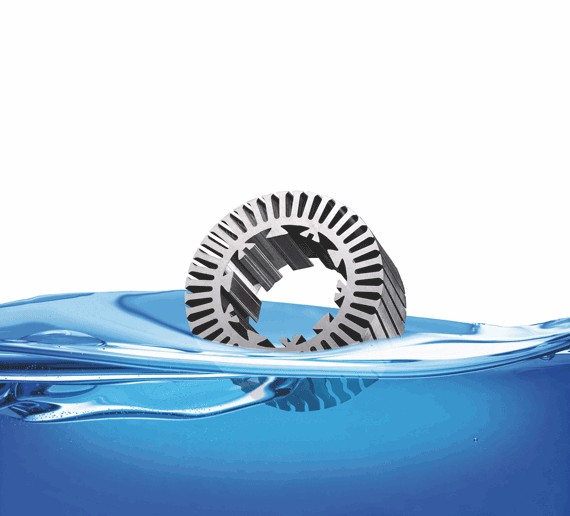

Axalta Coating Systems, a leading global supplier of liquid and powder coatings, introduces Voltatex 1175WL and Voltatex 1175WH – low and high viscosity versions, respectively – of a self-bonding electrical steel varnish, to its Energy Solutions’ product portfolio.

These two new electrical steel coatings replace the standard two component system, so no addition of a hardener or mixing is required.

Self-bonding characteristics have become increasingly important in the production of high-quality magnetic cores for stators and rotors.

Self-bonding products offer decisive manufacturing benefits as they deliver precise and reproducible adhesion.

Voltatex 1175WL and Voltatex 1175WH are designed to minimise any varnish being squeezed out of bonded stacks.

Self-bonding properties are therefore in high demand, particularly for the production of wind-turbine generators but also in the manufacture of motors for electric vehicles (EVs) and hybrid electric vehicles (HEVs).

"These two new Voltatex products offer very user-friendly handling,” explains Christoph Lomoschitz, Global Product Manager for Axalta’s Energy Solutions business.

"Because they are one component and offer specific viscosities, there is no viscosity adjustment necessary on the line so they are much easier to process, and they have a large curing window.

"They ensure that our portfolio of products will continue to deliver the outstanding performance that has established Axalta’s excellent industry reputation.”

Both Voltatex 1175WL and Voltatex 1175WH sustain peak temperature loads up to 180oC with sufficient bonding strength.

And thanks to the optimised surface quality, coiling, decoiling and punching of coated electrical steel coils is easy.

Voltatex 1175WL and Voltatex 1175WH offer longer shelf life and significantly improved handling with the same technical performance as standard two-component systems.

Voltatex 1175WL and Voltatex 1175WH are supplied in 200 litre drums or 1000 litre containers as a ready-to-use system without needing the addition of hardeners or accelerators.