More news

- New Managing Director of BASF’s Coatings division

- Global New Material International (GNMI) to acquire Merck’s Surface Solutions busine...

- Delta Coatings unveils plans for global eco-friendly HQ and plant

- PPG recognised for sustainability progress by FTSE4Good for sixth consecutive year

- ChemQuest expands Business Development team, names four VPs

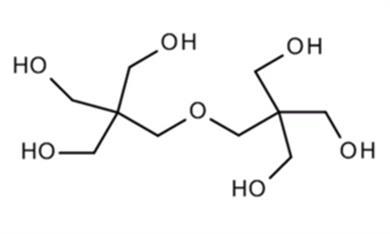

Perstorp has increased its capacity of di-pentaerythritol (Di-Penta) by 40%.

This is a result of improved efficiency and debottlenecking at all Di-Penta production sites.

Di-Penta is used in a vast number of applications, such as UV cured coatings, synthetic lubricants, high solids alkyd coatings, fire resistant Charmor™ coatings and lead-free PVC stabilisers.

Di-Penta has properties like thermo-stability, UV-stability, weather-, chemical- and scratch resistance.

It is also a very important raw material in many environmentally friendly applications.

As the largest global producer of Di-Penta, leading speciality chemicals company Perstorp is working on all fronts to meet the increased customer demand of Di-Penta and the performance it offers.

For years, the industry has suffered from shortages in the Di-Penta market.

To secure product availability, Perstorp has worked to maximise Di-Penta production capacity, which has resulted in a capacity increase and a fully available product.

Kent Hamacek, Product Manager, Advanced Polyols & Formates, said: "We strongly believe in Di-Penta and will work hard to continue to grow with our customers and our customers’ customers, bringing new and innovative solutions to market."

The complete strategy to meet customer demand for Perstorp Di-Penta now and in the future also includes a number of innovation projects focused on application development for complementary solutions.