More news

- New Managing Director of BASF’s Coatings division

- Global New Material International (GNMI) to acquire Merck’s Surface Solutions busine...

- Delta Coatings unveils plans for global eco-friendly HQ and plant

- PPG recognised for sustainability progress by FTSE4Good for sixth consecutive year

- ChemQuest expands Business Development team, names four VPs

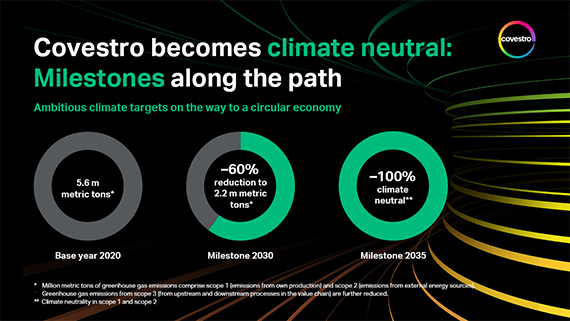

- Ambitious target: Net zero1 emissions by 2035 for scope 1 and scope 2

- 60% reduction in greenhouse gas emissions by 2030

- Every product to be offered in a climate neutral version in the future with major products already on offer today

Covestro has focused its corporate vision on becoming fully circular. To this end, the materials manufacturer wants to completely align its entire production and product range as well as all areas in the long-term to the circular concept. One concrete measure on this path is climate neutrality. Already in 2021, Covestro cut greenhouse gas emissions by 54% compared to 2005 and thus overachieved its previous sustainability target set for 2025.

Covestro has now defined a further bold target: the Group aims to become climate neutral and achieve net zero emissions by 2035 for scope 1 and scope 2. On the path to achieving this goal, the company plans to cut greenhouse gas emissions from its own production (scope 1) and from external energy sources (scope 2) by 60%2 to 2.2M metric tons by 2030. In addition, indirect greenhouse gas emissions from upstream and downstream processes in the value chain (scope 3) will be further reduced. Covestro intents to announce a reduction target for this by 2023.

To achieve net zero emissions, Covestro anticipates dedicated investments of an accumulated €250M to €600M by 2030, resulting in lower operating expenses of expected €50M to 100M annually due to growing energy efficiency. On its path to achieve net zero emissions, Covestro also expects an increase in operating expenses in the magnitude of a low three-digit million EUR amount annually. These cost assumptions are based on the historic experience that prices for fossil-based energies are lower than prices for renewable energies.

"For the past two years, we have been working at full speed on our vision to become fully circular. We have already reached important milestones on this path and continue to set ourselves ambitious goals. Thanks to this approach, we are a pioneer in our industry and have accomplished many successes. One next milestone are our bold climate targets,” said Dr Markus Steilemann, Chief Executive Officer of Covestro.

"In a circular economy, we can protect the climate, nature and resources and achieve sustainable growth that respects planetary boundaries. Covestro and the chemical industry are part of the solution. Sustainability cannot be done alone and will require a greater effort from everyone to achieve the goals of the Paris Climate Agreement. Policymakers, business and society must work together to achieve ambitious climate goals.”

Already now, based on Covestro’s previous greenhouse gas emissions reduction targets, major milestones have been reached. The Group met its ambition to reduce the greenhouse gas emissions by 50% per metric ton of product produced by 2025 earlier than expected. Thanks to successfully implemented operational excellence in all its major production sites, Covestro has cut emissions by 54% already in 2021, compared to base year 2005.

A key aspect of the new 2035 reduction target is meeting the goal of the Paris Climate Agreement, under which the world community aims to limit global warming to 1.5 degrees Celsius.

Three levers make a vital contribution to achieving the climate

- Production processes will be improved further and energy efficiency enhanced to achieve even more sustainable manufacturing. One focus is on reducing nitrous oxide emissions. That will be possible through greater use of innovative catalyst technology. In addition, production plants can be controlled more efficiently thanks to further digitalisation of the facilities and the use of digital technologies, while processes can be optimised using digital simulations. Digital technologies also help collect and track emissions data throughout the value chain.

- Covestro’s production sites worldwide are to be gradually converted to renewable electricity. That includes the use of offshore wind power, backed for example by a supply agreement with the energy provider Ørsted, which will cover 10% of the electricity required by the company’s sites in Germany from 2025 on. Onshore wind energy will also be used, for example under the power purchase agreement with ENGIE, that covers 45% of the electricity needs of the Covestro site in Antwerp, Belgium. About 10% of the electricity Covestro needs in Shanghai, China, already comes from the solar parks of Datang Wuzhong New Energy Co. In addition to the existing cooperation models with power suppliers, further agreements are being planned in order to achieve a net zero carbon footprint.

- Steam is an important energy source for chemical production processes. Converting steam generation from fossil to renewable energy sources is a challenge that Covestro intends to solve by various routes. To this end, the company is looking into the use of biogas and green natural gas as an energy source to generate renewable steam. Green hydrogen and green ammonia or green electricity could also be used as energy source for steam generation.

Covestro is updating and expanding its existing management system at the start of fiscal year 2022. The Group is also adding a sustainability component, measured by direct and indirect greenhouse gas emissions (scope 1 and 2) in 2022. Reducing greenhouse gas emissions (scope 1) has been a key performance indicator used as a component top management’s long-term compensation since January 2021.

Covestro will offer every product in a climate neutral version

"We aim to shift all our production processes and products completely to circular principles in the long-term, and we intend to support meeting our and climate objectives of our customers at the same time,” said Lynette Chung, Chief Sustainability Officer at Covestro. "Circularity and climate efforts are two sides of the same coin for us. With our climate neutral product offerings, our customers can thus expect us to fulfill both needs at the same time. We aim to make sustainability decisions as simple as possible for our customers.”

Focused on customer centricity, Covestro is already expanding its portfolio of climate neutral products continuously. Fundamental macro-economic challenges are addressed by enabling sustainable and unique solutions in key markets. The high demand for sustainable solutions is additionally growing due to global trends. Urbanisation, for example, increases the focus on constructing new energy-efficient buildings and renovating old ones. Large quantities of MDI are used worldwide as a raw material for making rigid polyurethane (PU) foam, a very effective insulation material for buildings and refrigerators. Now Covestro has added a climate neutral3 MDI to the product portfolio. 40M metric tons of CO2 equivalent could be saved by using PU insulation. The new MDI types are climate neutral from the cradle to the gate thanks to the use of precursors from ISCC PLUS-certified mass-balanced organic waste and residual materials.

Another groundbreaking example for sustainable products is Covestro’s world first climate neutral4 polycarbonate, made using raw materials from mass-balanced organic waste and residual materials as well as renewable energy. With the increasing trend of electromobility and the regulatory push for electric vehicles (EV), charging systems need to grow continuously, too. Using the climate neutral polycarbonate for EV charger could enable savings up to 450 kilotons CO2 equivalent by 2030. Covestro’s climate neutral polycarbonate is being shipped to customers since 2021.

1Achieving net zero greenhouse gas emissions is defined, as a balance between anthropogenic greenhouse gas emissions (from own operations and energy procurement) and anthropogenic greenhouse gas removals.

2 Reference value: base year 2020, 5.6M metric tons of greenhouse gas emissions.

3,4 Climate neutrality is the result of an internal assessment of a partial product life cycle from resource extraction (cradle) to the factory gate, also termed a cradle-to-gate assessment. The methodology for determining our ecological footprint is based on the standards ISO 14040/ISO 14044. Biogenic carbon sequestration is taken in to account in calculating it on the basis of provisional data from the supply chain. No compensation measures were used.