More news

Evonik Industries and SI Coatings, a company of the Huehoco Group, Wuppertal, Germany, have jointly developed a water-based primer for the pretreatment of steel prior to coating in the fluidised-bed process with VESTOSINT® polyamide 12 powder. Polyamide coatings on metal serve to protect against corrosion. It is therefore important that they are applied uniformly, do not peel off and cannot be infiltrated by water. In addition, they must be resilient against external influences so that the coating provides lasting protection. Evonik’s VESTOSINT polyamide 12 fluidised bed powders have proven their performance here for many years. Until now, large-area steel parts, especially concave surfaces, were pretreated with solvent-containing primers when exceptional adhesion was required, for example, in contact with water.

Reliable and sustainable

"Evonik has firmly anchored the idea of environmental compatibility in its corporate strategy. Therefore, for the processing of VESTOSINT we were looking for a partner with whom we could develop a water-based primer that is precisely matched to our polyamide powder. We found this partner in SI Coatings," said Dr Dominic Störkle, head of the Additive Manufacturing & Material Solutions product line at Evonik, describing the motivation for the collaboration. Evonik’s many years of expertise in fluidised bed coating with polyamide powder and SI Coatings’ know-how in the field of adhesion promoters ideally complemented each other. The result: a reliable water-based primer that does not require any special work protection technology such as fume hoods. The product is label-free according to the Globally Harmonised System of Classification and Labelling of Chemicals (GHS). The residual solvent content, reported as volatile organic compounds (VOCs), is less than two percent. "Since we are a globally active company, we can offer the jointly developed primer to Evonik customers worldwide and also in small quantities," said Managing Director Andreas Kunz of SI Coatings, emphasising the advantage of the partnership.

The new primer Si Coatings 100011-00L with water hazard class WGK1 has a shelf life of six months when stored frost-free. It can be applied by brushing, spraying, dipping or doctoring and baked at about 300°C during heating for the fluidised bed process with VESTOSINT. One possible application is cardan shafts, which are coated on both the outside and the inside.

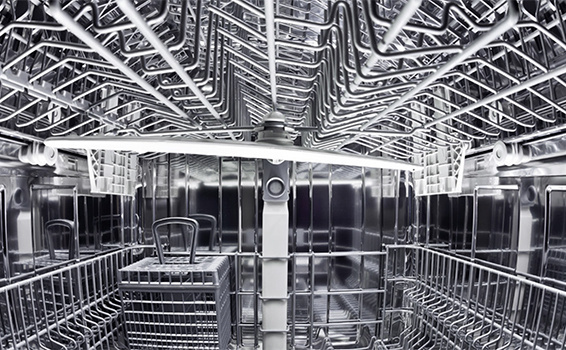

Evonik markets the high-performance plastic polyamide 12 as a powder under the name VESTOSINT, for example, for coating dishwasher baskets, metals in household goods, the automotive industry or medical technology. The Group is a global leader in the production of polyamide 12 compounds, which are in high demand in highly attractive markets such as the automotive industry, oil and gas production and the medical and sports sectors.

SI Coatings in Wuppertal develops and produces technical, functional and decorative coatings, as well as adhesion promoters for a wide range of applications.