More news

Researchers at the National Institute of Standards and Technology (NIST) have developed a nano-scale coating for solar cells that enables them to absorb about 20% more sunlight than uncoated devices.

The coating, applied with a technique that could be incorporated into manufacturing, opens a new path for developing low-cost, high-efficiency solar cells with abundant, renewable and environmentally friendly materials.

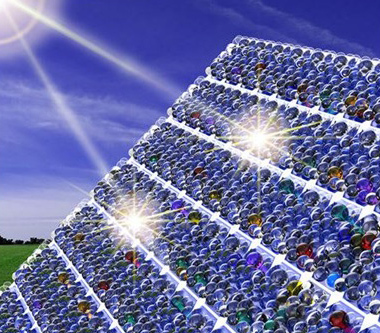

The coating consists of thousands of tiny glass beads, only about one-hundredth the width of a human hair.

When sunlight hits the coating, the light waves are steered around the nano-scale bead, similar to the way sound waves travel around a curved wall such as the dome in St Paul’s Cathedral in London.

At such curved structures, known as acoustic whispering galleries, a person standing near one part of the wall easily hears a faint sound originating at any other part of the wall.

Whispering galleries for light were developed about a decade ago but researchers have only recently explored their use in solar-cell coatings. In the experiment devised by a team including Dongheon Ha of NIST and the University of Maryland’s NanoCenter, the light captured by the nano-resonator coating eventually leaks out and is absorbed by an underlying solar cell made of gallium arsenide.

Using a laser as a light source to excite individual nanoresonators in the coating, the team found that the coated solar cells absorbed on average 20% more visible light than bare cells.

The measurements also revealed that the coated cells produced about 20% more current.

The study is the first to demonstrate the efficiency of the coatings using precision nano-scale measurements, said Ha.

"Although calculations had suggested the coatings would enhance the solar cells, we could not prove this was the case until we had developed the nano-scale measurement technologies that were needed,” he noted.

The team also devised a rapid, less-costly method of applying the nanoresonator coating.

Researchers had previously coated semiconductor material by dipping it in a tub of the nano-resonator solution.

The dipping method takes time and coats both sides of the semiconductor even though only one side requires the treatment.

In the team’s method, droplets of the nano-resonator solution are placed on just one side of the solar cell.

A wire-wound metal rod is then pulled across the cell, spreading out the solution and forming a coating made of closely packed nano-resonators.

This is the first time that researchers have applied the rod method, used for more than a century to coat material in a factory setting, to a gallium arsenide solar cell.

"This is an inexpensive process and is compatible with mass production,” said Ha.

Caption: The nano-resonator coating, consisting of thousands of tiny glass beads deposited on solar cells