More news

- New Managing Director of BASF’s Coatings division

- Global New Material International (GNMI) to acquire Merck’s Surface Solutions busine...

- Delta Coatings unveils plans for global eco-friendly HQ and plant

- PPG recognised for sustainability progress by FTSE4Good for sixth consecutive year

- ChemQuest expands Business Development team, names four VPs

PPG has announced a new name, PPG OptiGuard™ series (formerly LineGuard) for its advanced coatings solutions, developed to help automotive original equipment manufacturers (OEM), tier suppliers and industrial customers reduce the time, cost, risk and environmental impact associated with cleaning paint shop equipment. The new name aligns the offering with the global PPG Optima Solutions™ product and service portfolio.

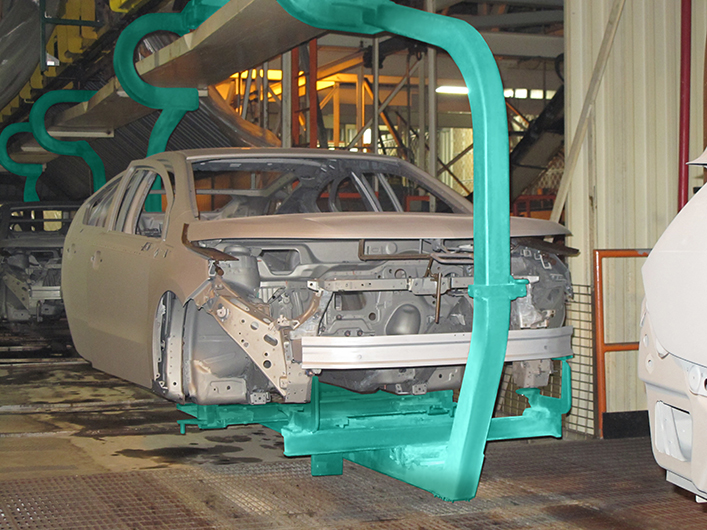

The PPG OptiGuard series features a variety of technologies for mass-production paint shop environments, including durable, insulative and nonstick coatings that help simplify the cleaning of vehicle carriers, racks, jigs, floor grids and other equipment. These coatings resist the buildup of coatings, chemicals, grease, dirt and other contaminants, making it easy to keep equipment clean and avoid unnecessary downtime.

The coatings’ nonstick properties enable customers to reduce the number of equipment cleaning cycles by up to 75%, leading to significant savings in labour, materials, energy, water and waste filtration and removal.

“PPG OptiGuard solutions help businesses reduce operating costs, increase process efficiency, improve quality, better protect their employees and manage their environmental footprints,” said Anne-Sybil Bragadir, PPG Global Business Development Director, PPG Optima Solutions. “These innovative turnkey solutions demonstrate our commitment to provide unsurpassed expertise and value at multiple levels of our customers’ businesses.”

Vehicle and industrial businesses are forced to regularly pull paint shop equipment from production to remove contaminant buildup. In many cases, thoroughly cleaning this equipment requires time-intensive and costly spray blasting using extremely high-water pressures, burning and/or chemical cleaning materials. Equipment protected with a PPG OptiGuard coating can be cleaned significantly faster, at lower cost and without the need to use potentially dangerous practices.

The PPG OptiGuard series includes specialized high-strength polymer and solvent-free epoxy coatings ideally suited for topcoat carriers, paint booth racks, electrocoat hangars, floor grids and any equipment commonly exposed to high-temperature ovens. To help customers avoid unnecessary equipment downtime, PPG Optima Solutions representatives manage each step of the project, including scheduling, equipment preparation, application and any related transportation needs.