More news

In an effort to curb global warming, Purdue University engineers have created the whitest paint yet. Coating buildings with this paint may one day cool them off enough to reduce the need for air conditioning, the researchers say.

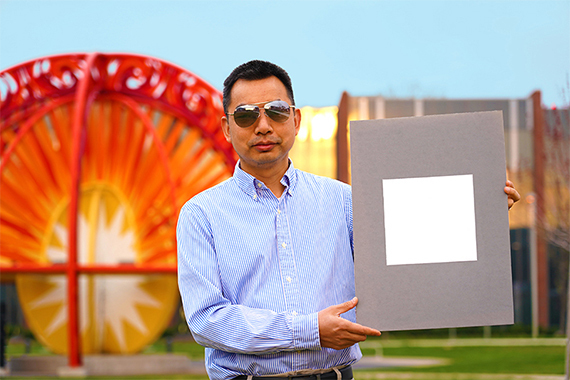

In October, the team created an ultra-white paint that pushed limits on how white paint can be. Now they’ve outdone that. The newer paint not only is whiter but also can keep surfaces cooler than the formulation that the researchers had previously demonstrated. "If you were to use this paint to cover a roof area of about 1000 square feet, we estimate that you could get a cooling power of 10kW. That’s more powerful than the central air conditioners used by most houses,” said Xiulin Ruan, a Purdue Professor of mechanical engineering.

The researchers believe that this white may be the closest equivalent of the blackest black, "Vantablack,” which absorbs up to 99.9% of visible light. The new whitest paint formulation reflects up to 98.1% of sunlight – compared with the 95.5% of sunlight reflected by the researchers’ previous ultra-white paint – and sends infrared heat away from a surface at the same time. Typical commercial white paint gets warmer rather than cooler. Paints on the market that are designed to reject heat reflect only 80%-90% of sunlight and can’t make surfaces cooler than their surroundings.

The team’s research paper showing how the paint works published last Thursday (April 15) as the cover of the journal ACS Applied Materials & Interfaces.

What makes the whitest paint so white

Two features give the paint its extreme whiteness. One is the paint’s very high concentration of a chemical compound called barium sulphate, which is also used to make photo paper and cosmetics white.

"We looked at various commercial products, basically anything that’s white,” said Xiangyu Li, a Postdoctoral Researcher at the Massachusetts Institute of Technology, who worked on this project as a Purdue PhD student in Ruan’s lab. "We found that using barium sulphate, you can theoretically make things really, really reflective, which means that they’re really, really white.”

The second feature is that the barium sulphate particles are all different sizes in the paint. How much each particle scatters light depends on its size, so a wider range of particle sizes allows the paint to scatter more of the light spectrum from the sun.

"A high concentration of particles that are also different sizes gives the paint the broadest spectral scattering, which contributes to the highest reflectance,” said Joseph Peoples, a Purdue PhD student in mechanical engineering.

There is a little bit of room to make the paint whiter, but not much without compromising the paint.

"Although a higher particle concentration is better for making something white, you can’t increase the concentration too much. The higher the concentration, the easier it is for the paint to break or peel off,” Li said.

How the whitest paint is also the coolest

The paint’s whiteness also means that the paint is the coolest on record. Using high-accuracy temperature reading equipment called thermocouples, the researchers demonstrated outdoors that the paint can keep surfaces 19 degrees Fahrenheit cooler than their ambient surroundings at night. It can also cool surfaces 8 degrees Fahrenheit below their surroundings under strong sunlight during noon hours.

The paint’s solar reflectance is so effective, it even worked in the middle of winter. During an outdoor test with an ambient temperature of 43 degrees Fahrenheit, the paint still managed to lower the sample temperature by 18 degrees Fahrenheit.

This white paint is the result of six years of research building on attempts going back to the 1970s to develop radiative cooling paint as a feasible alternative to traditional air conditioners.

Ruan’s lab had considered more than 100 different materials, narrowed them down to 10 and tested about 50 different formulations for each material. Their previous ultra-white paint was a formulation made of calcium carbonate, an earth-abundant compound commonly found in rocks and seashells.

The researchers showed in their study that like commercial paint, their barium sulphate-based paint can potentially handle outdoor conditions. The technique that the researchers used to create the paint also is compatible with the commercial paint fabrication process.

Patent applications for this paint formulation have been filed through the Purdue Research Foundation Office of Technology Commercialization. This research was supported by the Cooling Technologies Research Center at Purdue University and the Air Force Office of Scientific Research through the Defense University Research Instrumentation Program (Grant No.427 FA9550-17-1-0368). The research was performed at Purdue’s FLEX Lab and Ray W. Herrick Laboratories and the Birck Nanotechnology Center of Purdue’s Discovery Park.